Ordinary sintered alumina needs to add a small amount of sintering aids such as MnO, CuO, TiO2, etc. during the sintering process to reduce the sintering temperature and sintering performance of alumina ceramics, and then promote sintering densification by liquid phase sintering mechanism. Therefore, the porosity of the sintered body is low, the crystals are fine and dense, but its thermal shock resistance is poor.

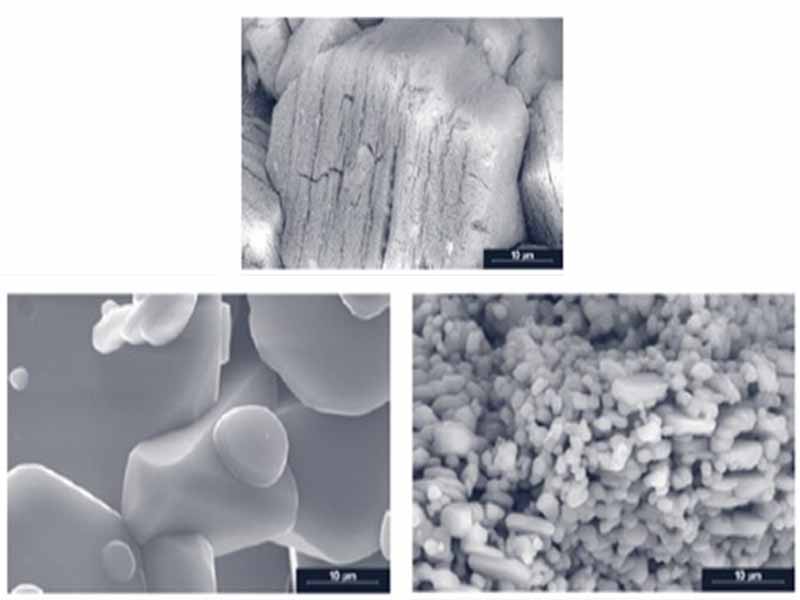

Sintered tabular alumina is sintered without any additives at a high temperature over 1800°C. Its microscopic observation is a fully developed hexagonal plate-shaped α-alumina crystal, and the grain size is generally greater than 200 μm. Sintered tabular alumina has excellent volume stability and thermal shock resistance In addition, it has extremely high refractoriness, excellent mechanical strength and wear resistance, superior creep resistance and spalling resistance, very high chemical purity , excellent dielectric properties and anti-acid and alkali corrosion ability, can be widely used in steel, casting and ceramic industries, as well as chemical industry heat exchange, energy storage, environmental protection facilities, etc.

Tabular alumina semi-finished products and unshaped products:

Application fields: kiln industry technology/kiln accessories, refractory materials, high temperature materials, ceramic materials

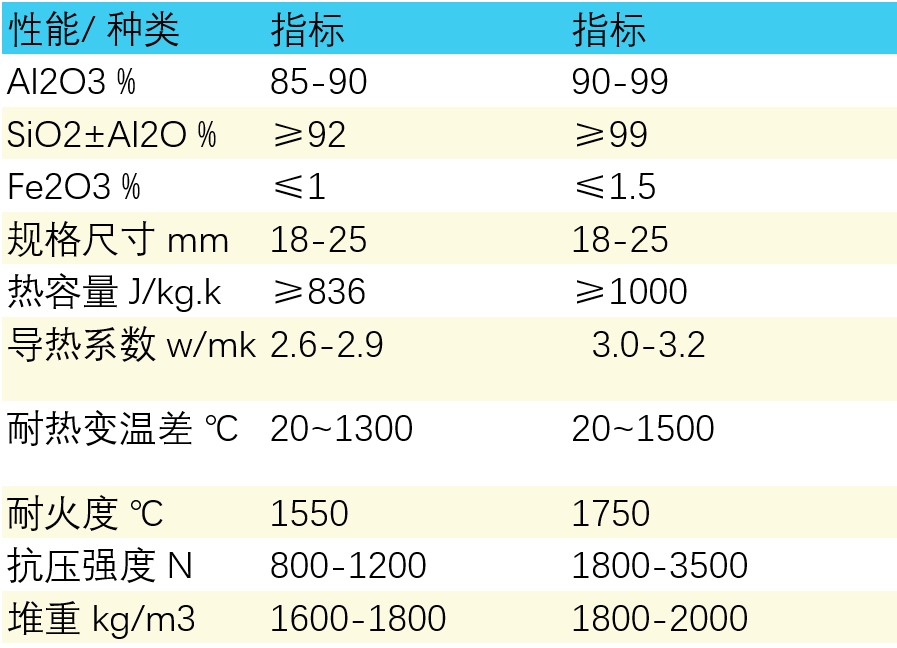

Properties of Tabular Alumina

1. The refractoriness is ≥1800℃, and its melting point is as high as 2050℃.

2. It has a coarse and well-developed -Al2O3 crystal structure, and the creep resistance of several numbers.

3. Plate-shaped crystal structure, small open pores, low apparent porosity, low water absorption; more internal closed pores, good thermal shock resistance and peeling resistance.

The use of tabular alumina

1. Refractory materials, furnace materials, aggregates, castable materials, pounding materials, plastic materials, pressing materials, projection materials, spray coatings, vibration materials, refractory mud, etc.;

2. Wear-resistant coatings, refractory coatings, wear-resistant machinery, etc.;

3. Smelting, casting, steel mills, power plants, etc.;

4. Ceramic deburring, surface treatment, etc.;

5. Refractory bricks, refractory ceramics, etc.

Copyright © 2025 Alumina Technology (Qingdao)New Materials LTD All Rights Reserved.